How Signarama Transformed Its Packaging with HEAT SEAL

At Signarama, delivering high-quality signage solutions goes beyond just designing and manufacturing signs—it extends to every aspect of the customer experience, including packaging and delivery. As the largest franchise in the global Signarama network, the company specializes in vehicle graphics, laser engraving, interior ADA signs, and full-scale sign manufacturing. However, as they expanded into the national marketplace, they faced challenges in ensuring that their products arrived in pristine condition.

Reducing Shipping Damages

Before integrating HeatSeal’s technology, one of Signarama’s biggest challenges was ensuring that their signs arrived at their destinations without damage. Given the delicate nature of signage materials—ranging from laser-engraved plaques to full-scale manufactured signs—improper packaging could lead to scratches, dents, or even structural failure during transit. With increasing national shipments, Signarama needed a solution to enhance product protection, minimize returns, and strengthen brand reliability. Improved packaging techniques, such as custom inserts and cushioning materials, secured items more effectively within boxes, reducing damage and ensuring pristine product arrival. Better packaging minimized product returns, saving costs and improving customer experience. Consistent product delivery met customer expectations, building trust and reinforcing the brand’s image as a leader in quality. HeatSeal’s Skin-Packaging solution, improved product security and significantly reduced damaged shipments and return requests.

Improving Presentation When Customers Open Their Packages

Beyond just protecting products, packaging plays a crucial role in shaping a customer’s first impression. Signarama wanted to elevate the unboxing experience by creating a presentation that reflected the quality of their brand.

The previous packaging sometimes appeared inconsistent or rushed, leading to concerns about professionalism. With HeatSeal’s solution, Signarama was able to ensure a clean and professional presentation by using uniform sealing and secure product placement. This instills confidence in customers from the moment they open the box, enhances branding by well-packaging products, and reinforces the company’s commitment to high standards and attention to detail. Additionally, they were able to reduce frustration by eliminating packaging inconsistencies, ensuring customers had a smooth and enjoyable unboxing experience. This not only strengthened customer trust but also contributed to positive word-of-mouth and repeat business.

Standardizing Packaging While Maintaining Efficiency

As Signarama expanded, packaging consistency became a growing concern. Different team members using varied packing techniques led to inconsistency across orders. This lack of standardization made it harder to maintain efficiency while scaling operations. They needed a repeatable, standardized approach to ensure every package met the same high standards, reducing variability. They needed a more efficient process, reducing the time spent manually sealing and checking each package, and speeding up fulfillment. Finally, they wanted employees to be able to focus on critical tasks instead of troubleshooting packaging issues and enhancing team productivity.

Integrating Better Quality Control (QC) and Documentation

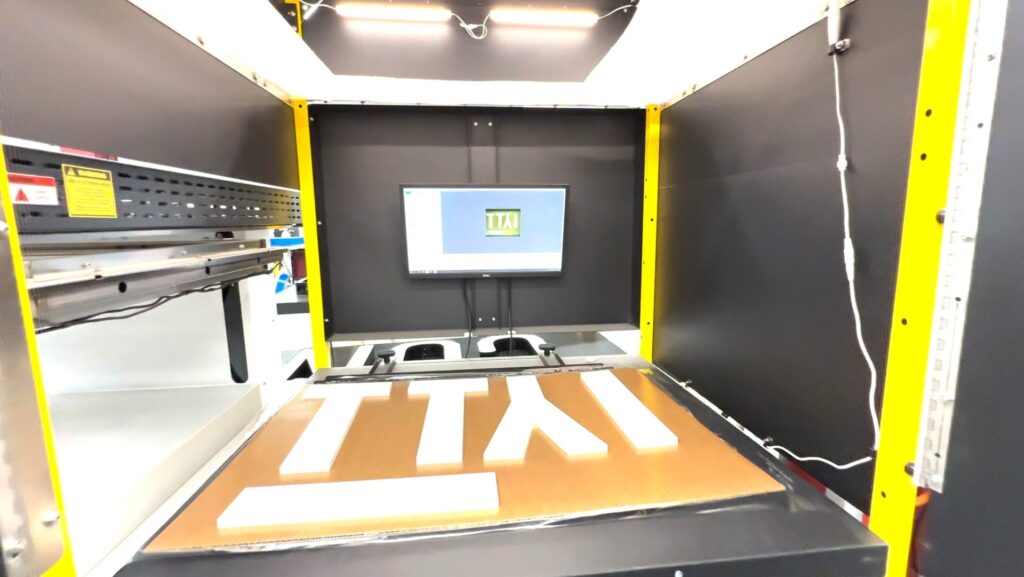

HeatSeal’s solution, one of its most innovative aspects, integrated seamlessly with Signarama’s QC system. The company aimed to track and verify packaging quality while simultaneously maintaining a comprehensive record of each shipment.

By integrating a camera system and cloud-based storage, Signarama was able to capture proof of quality. Photos of each packaged product ensured that every order met internal quality standards before leaving the facility. This meticulous documentation process not only guaranteed consistent products with the company’s high standards but also served as a tangible record of quality assurance. Detailed images promptly identified and addressed potential defects, reducing the likelihood of defective products reaching customers. This proactive approach instilled confidence in the team that the products were in optimal condition.

Additionally, Signarama created a digital record for accountability. If a customer reported an issue, the company could quickly reference past shipments to confirm proper packaging at departure. This digital archive of shipment details provided an essential point of reference for swift customer concern resolution with accurate, evidence-based responses. It minimized disputes by offering clear, visual proof of goods’ condition before dispatch, upholding transparency and accountability. This system also facilitated efficient tracking of shipment histories, invaluable in resolving discrepancies.

Improving internal auditing, Signarama streamlined quality assessments and identified potential areas for improvement. A comprehensive digital log facilitated thorough audits of packaging processes and product handling standards. This systematic approach enabled continuous improvement initiatives, allowing the business to pinpoint inefficiencies or recurring issues and implement necessary changes. Internal teams could analyze data trends over time to make informed decisions, ultimately enhancing operational efficiency and product quality. This robust auditing process not only bolstered the company’s quality control framework but also supported strategic planning and development.

This step not only enhanced operational oversight but also provided customers with added reassurance, knowing that their orders were carefully handled and inspected.

A Collaborative Approach to Problem-Solving

Instead of offering a generic product, Heat Seal collaborated closely with Signarama to understand their unique needs. Mathew Godwin, COO/CFO at Signarama, described their initial interactions as a refreshing change, as HeatSeal’s team genuinely listened and ensured that the solution addressed various aspects of their business:

“Initially, we conducted a thorough analysis to comprehend Signarama’s packaging process. We evaluated the types of materials used, the volume of products packaged, and the desired speed and efficiency of the sealing process. We then researched various manufacturers and models of heat-sealing machines, focusing on those that offered the capabilities required for precise and consistent sealing. The selection process involved extensive trials and testing to ensure that the chosen machine could seamlessly integrate with existing workflows while maintaining high-quality standards.”

Upon implementation, HeatSeal’s technology not only enhanced packaging consistency but also streamlined Signarama’s internal workflow. The customized machine incorporated an integrated camera system that captured images of each packaged product, enabling Signarama to store images in their cloud-based Quality Control (QC) system; a process that involves uploading and saving images to a secure, cloud-based QC system. The cloud-based platform ensures that images are readily accessible from any location and can be shared among team members or clients as necessary. Furthermore, the cloud system provides scalable storage solutions, accommodating the growth of the number of images without the requirement for additional hardware.

Additionally, Heat Seals customized solution enabled Signarama to offer proof-of-quality assurance to their clients by compiling and presenting documentation and photographic evidence that demonstrates the quality of a client’s order as it was when it was packaged and shipped. This in turn reduces the time spent on manual quality checks by implementing a semi-automated processes which substantially reduces the time cost of manual quality checks.

A Strong Partnership for the Future

Reflecting on the collaboration, Godwin emphasized the importance of choosing the right partners in business;

“People don’t know what you want unless you communicate it. When you find the right company that listens and works with you, that’s what makes a great partnership. Working with HeatSeal has been a breath of fresh air, and I’d encourage anyone facing similar challenges to have that conversation with them.”

As Signarama continues to grow, the company’s investment in innovation and efficiency—along with strategic partnerships like HeatSeal—ensures that they can deliver exceptional signage solutions with confidence.